Infrastructure Service Solution

Services for Storage

Move to new storage technology faster with less disruption to speed your time to value.

Converged and Hyperconverged Services

Achieve faster ROI and simplify and streamline converged and hyperconverged implementations.

Managed Services

Drive business value faster with remote infrastructure, enterprise and custom applications management and managed services.

Start Faster

Starter packs get you up and running faster to improve time to value.

Achieve More

Gain the skill and expertise to fully optimize cost and drive efficiency.

Gain Control

Deliver more consistent service levels and avoid disruption.

Do Better

Enhance customer experience and increase brand loyalty.

IOT Solution

Product overview

The Internet of Things (IoT) has drastically transformed the manufacturing and field service business. With it, companies are no longer limited to managing the maintenance of production assets based on equipment age or usage to stay ahead of costly failures.

Itas Solutions IoT Service Hub enables organizations who manage industrial equipment assets to maximize operational efficiency. Delivering autonomous predictive service capabilities, the solution intelligently predicts failures, initiates corrective actions, and facilitates the repair process—all to prevent the failures before they occur.

Our IoT Service Hub solution is a combination of cloud-based software, data science, and integration services that allow organizations responsible for managing industrial equipment assets to transform their maintenance model from repair and replace to predict and prevent.

Business outcomes

- Increase equipment uptime – Uses machine learning to identify equipment anomalies before failures occur, optimizing productivity, reducing maintenance costs, and increasing operational efficiencies

- Improve service delivery – Reduces equipment operating costs by transitioning from reactive to predictive maintenance, extending the useful life of equipment and optimizing service personnel

- Create new service revenue streams – Produces recurring revenue streams by gathering and analyzing data that complements predictive maintenance, and presents opportunities to monetize services

Feature functionality

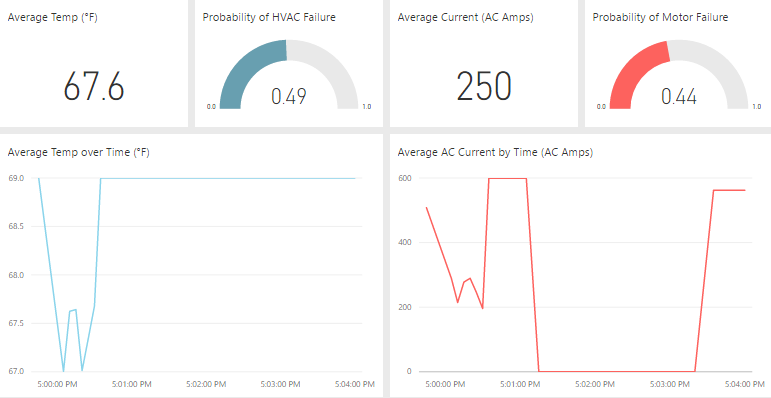

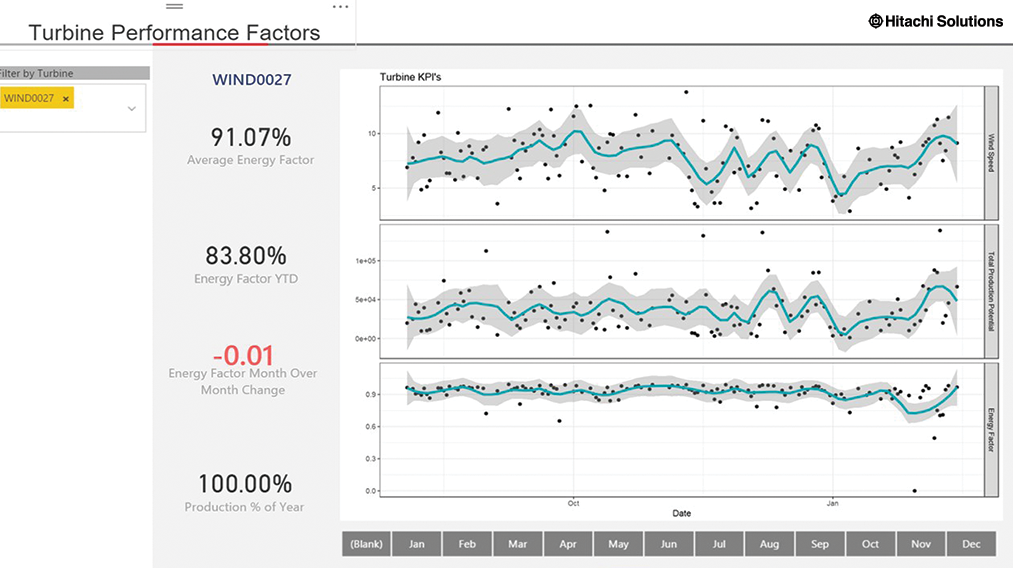

Predictive maintenance

Pinpoints equipment and component issues and failures before they occur, leading to reduced maintenance costs and unplanned equipment downtime, and extending useful life of capital equipment.

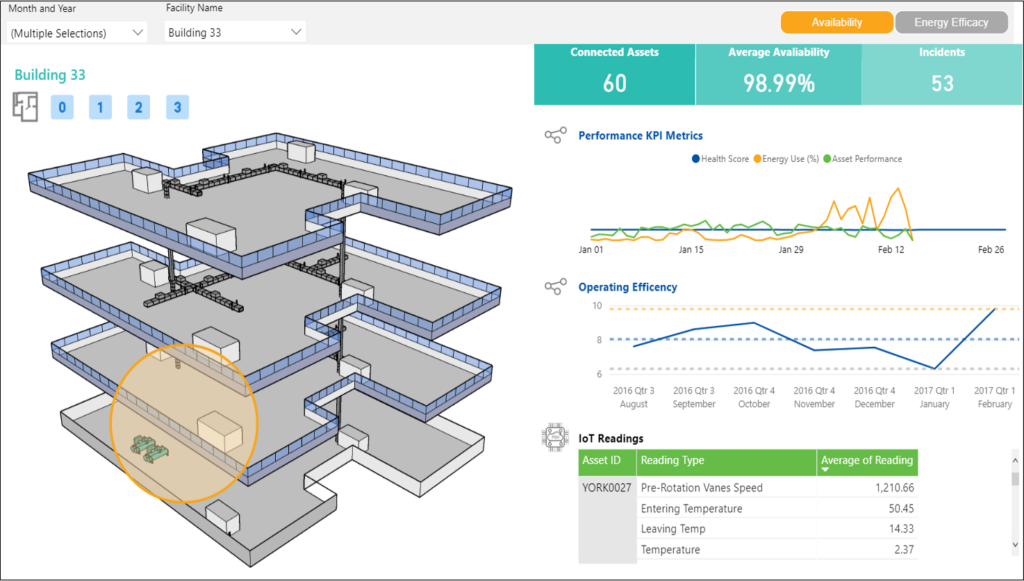

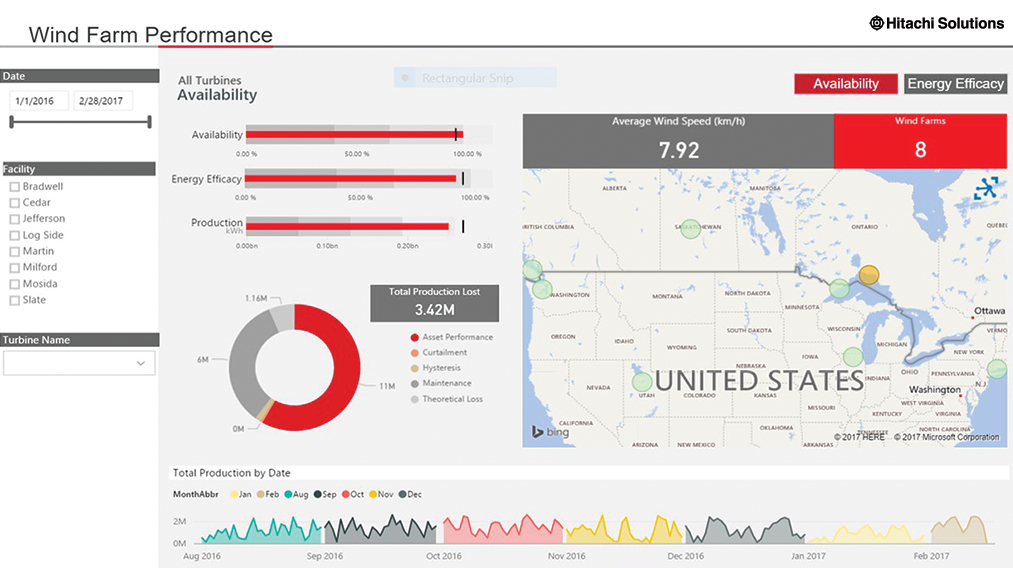

Equipment monitoring and telemetry

Collects data at remote or inaccessible points and transmits for monitoring to increase the understanding of what’s occurring at the edge and transition from reactive to proactive maintenance.

Field service automation and repair

Field service automation and repair</strong><br /> Monitors and assesses machine “health,” making it possible to know exactly what needs to be repaired, along with the necessary parts and technical skill levels. Automation also includes the ability to track parts, technicians, equipment warranties, and automate the flow of work orders, invoices, inventory, time/expenses, and more.

Rules-based equipment management

Uses rules-based diagnostic systems to analyze equipment performance, detect abnormalities, and trends. Sensors installed in equipment derive real-time and near-real-time data for analysis.

Production optimization

Increases production yield and quality by collecting and analyzing machine performance to identify potential issues, discover root causes of problems, and reduce break-fix incidents.

What-if simulation

Makes “virtual” changes to machine functionality to determine potential outcomes, such as increasing the speed of an assembly line by 10 percent to test the potential wear and tear on components.

Equipment certification management

Automates tracking of details on equipment and assets, including ensuring equipment complies with regulatory standards.

Energy utilization and fuel consumption

Uses data captured at the edge to assess the energy usage of machinery and vehicles, with the goal of reducing energy or fuel consumption.

Fleet and route optimization

Uses IoT devices to monitor tank levels, driver behavior, and fuel utilization to improve efficiencies and reduce costs. This data is also used to improve equipment turnaround and more knowledgeably maintain and fix vehicles.

Workplace safety

Improves worker safety by predictively identifying environmental and machinery issues and repairing them before they potentially cause a safety hazard.

Big Data and Hadoop Solution

The term big data applies to very large, complex, or dynamic datasets that need to be stored and managed over a long time. To derive benefits from big data, you need the ability to access, process, and analyze data as it is being created. However, the size and structure of big data makes it very inefficient to maintain and process it using traditional relational databases.

Big data solutions re-engineer the components of traditional databases—data storage, retrieval, query, processing—and massively scales them.

ITAS Big Data Overview

ITAS increases speed-of-thought analysis against even the largest of big data stores by focusing on the features that deliver performance.

- Instant access—ITAS provides visual tools to make it easy to define the sets of data that are important to you for interactive analysis. These data sets and associated analytics can be easily shared with others, and as new business questions arise, new views of data can be defined for interactive analysis.

- High performance platform—ITAS is built on a modern, lightweight, high performance platform. This platform fully leverages 64-bit, multi-core processors and large memory spaces to efficiently leverage the power of contemporary hardware.

- Extreme-scale, in-memory caching—ITAS is unique in leveraging external data grid technologies, such as Infinispan and Memcached to load vast amounts of data into memory so that it is instantly available for speed-of-thought analysis.

- Federated data integration—Data can be extracted from multiple sources, including big data and traditional data stores, integrated together and then flowed directly into reports, without needing an enterprise data warehouse or data mart.